Introduction to the WEP 992D Soldering Iron Kit

The WEP 992D-III 2-in-1 soldering and hot air rework station is a versatile tool designed for both hobbyists and professional technicians involved in electronics repair. This dual-function station combines two essential functions—soldering and hot air reworking—into one comprehensive unit, making it ideal for a range of applications, from general electronics repairs to intricate surface-mounted device (SMD) work. By integrating both functionalities, the WEP 992D Soldering Iron Kit aims to streamline the workflow of users who frequently switch between soldering and reworking tasks.

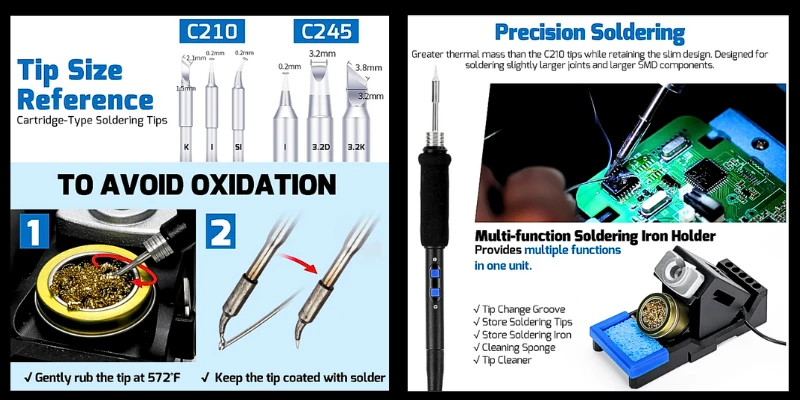

One of the standout features of the WEP 992D-III is its compatibility with C245 soldering cartridges. This compatibility not only expands the range of soldering tasks that can be efficiently performed but also ensures ease of access to various tip sizes and shapes that are pivotal for different jobs. Whether it involves delicate soldering on computer circuit boards, solder joints on integrated circuits (ICs), or robust connections on larger components, this station provides the necessary functionality and flexibility.

Additionally, the WEP 992D-III is particularly well-suited for professionals who engage in SMD and IC repairs, where precision and control are paramount. The hot air rework feature facilitates the removal and placement of SMD components, making it a practical choice for technicians specializing in electronic assembly and repair. Furthermore, the intuitive design of the unit ensures that both novice users and industry experts can operate it with ease, enhancing its appeal among a wide audience in the electronics repair community. Ultimately, the WEP 992D-III serves as a reliable and efficient tool, promising to enhance productivity and precision in various soldering and reworking tasks.

Key Features and Specifications

The WEP 992D-III 2-in-1 soldering and hot air rework station is designed for both hobbyists and professionals alike, providing a range of features that enhance its usability and efficiency. One of the standout specifications of this device is its high-power soldering iron, rated at 1000W. This powerful soldering iron ensures quick heating and efficient soldering, significantly reducing the waiting time for the tool to reach its optimal temperature. Such a feature is particularly advantageous for users involved in high-volume production or intricate repair work where speed is essential.

In addition to the soldering capabilities, the WEP 992D-III also boasts an adjustable temperature range for the hot air rework station. This flexibility allows users to set the temperature according to the specific requirements of their components. Generally, a range of 100°C to 480°C is available, thereby accommodating various heat-sensitive materials. The ability to regulate temperature combined with adjustable airflow settings makes it suitable for a variety of tasks, from desoldering small electronic components to heat-shrinking tubing.

The WEP 992D-III is versatile enough to handle an array of electronic components, including SMD (Surface-Mount Devices) and traditional components. This capacity means that technicians can use the station effectively for both modern and older devices, thereby expanding the unit’s functionality. The kit comes equipped with essential accessories, including multiple hot air nozzles that cater to different sizes and shapes of components, enhancing precision and control during operation. Additionally, it includes a precision soldering iron that ensures detailed work, further making this unit a valuable assistant for all soldering and reworking tasks.

Operational Excellence: Soldering and Rework Capabilities

The WEP 992D-III 2-in-1 Soldering and Hot Air Rework Station distinctly excels in its operational features, designed to enhance the efficiency and effectiveness of complex PCB repairs. This dual-functionality device allows users to operate both the soldering iron and hot air gun simultaneously, significantly streamlining the workflow for technicians dealing with intricate electronic components. The ability to execute soldering and hot air rework concurrently ensures that users can undertake tasks that require both methods without needing to pause and switch equipment, thereby saving valuable time.

At the core of the WEP 992D-III’s soldering capabilities is its C245-compatible soldering iron. This specific compatibility is paramount, as it opens a wide array of high-performance soldering tips, enabling precise application based on the user’s needs. The soldering iron heats up quickly and maintains a consistent temperature, which is critical for delicate soldering jobs on PCBs. Technicians will appreciate that the iron is designed not only for efficiency but also for comfort, featuring an ergonomic handle that minimizes fatigue during prolonged use.

Moreover, the hot air gun incorporated in the WEP 992D-III offers adjustable airflow and temperature settings, providing users the flexibility to adapt to various rework scenarios. Whether it is desoldering surface-mounted devices or heat-shrinking components, the heat gun’s precise control aids in the achievement of flawless results. Overall, the operational excellence of the WEP 992D-III reinforces its position as a valuable tool in the realm of soldering and rework stations, ensuring that users can perform high-quality repairs with confidence and ease. This focus on usability and efficiency greatly enhances the overall user experience in the challenging field of PCB repairs.

User-Friendly LCD Display

The WEP 992D-III 2-in-1 Soldering and Hot Air Rework Station is designed with an intuitive user interface that is accentuated by its user-friendly LCD display. This display plays a crucial role in enhancing the overall operating experience for both beginners and seasoned professionals in electronics repair and assembly. It features independent displays for both the soldering and hot air rework functions, allowing users to easily monitor and control each process in real time. This distinct separation of information eliminates confusion, enabling users to concentrate on their tasks without the need for constant toggling between different settings.

The LCD display provides clear and bright readouts of important metrics, such as temperature settings and status indicators, which are essential for ensuring precision during soldering and desoldering operations. Users can quickly adjust the temperature settings for each station via an easy-to-navigate menu, ensuring they can adapt to various solder types and components with convenience. The real-time monitoring feature is particularly advantageous as it allows users to make timely adjustments to the temperature during operation, reducing the risks of overheating components or solder failure.

Durability and Low-Wear Mode

The WEP 992D-III 2-in-1 soldering and hot air rework station is engineered with a focus on durability and longevity, two critical factors that users typically consider when investing in such equipment. One of the distinguishing features of this station is its integrated low-wear mode, which significantly enhances the lifespan of both the soldering iron and hot air gun. This mode operates under controlled temperature settings, minimizing the risk of overheating and thermal fatigue that can compromise the performance and lifespan of the heating elements.

When in low-wear mode, the WEP 992D-III intelligently regulates the temperature, ensuring that the components are not subjected to excessive thermal stress during operation. This design choice is particularly beneficial for hobbyists and professionals who engage in extensive soldering projects, allowing for prolonged use without the common issues associated with wear and tear. Moreover, maintaining the integrity of the heating elements is essential, as a compromised soldering iron can lead to inconsistent heating, affecting solder quality and precision in delicate electronics work.

Additionally, the robust construction of the WEP 992D-III ensures that the physical components are built to withstand regular handling and operation. The soldering iron’s ergonomic design, coupled with high-quality materials, lends itself to a comfortable user experience without sacrificing durability. Similarly, the hot air gun features a well-designed nozzle that complements its functionality while resisting wear over time. With these durability-centric features, the WEP 992D-III station emerges as a reliable choice for both novice and experienced users, making it an investment worth considering for anyone seeking a dependable soldering solution.

Convenience of Preset and Menu Options

The WEP 992D-III 2-in-1 soldering and hot air rework station is designed with user convenience at the forefront, particularly through its extensive preset and menu options. This dual functionality allows users to switch between soldering and hot air rework seamlessly, making it an essential tool for various electronic repairs and projects. One of the standout features of the WEP 992D-III is its ability to store preferred temperature and air volume settings within easy-to-access preset channels. This customization means that, when switching tasks, users can quickly select their preconfigured settings rather than having to recalibrate the tools every time.

The capability to save settings not only enhances the workflow but also minimizes the risk of errors that can occur when adjusting temperatures and air volumes manually. With the ability to juggle multiple tasks like PCB assembly or component desoldering, the WEP 992D-III caters to individual user preferences efficiently. Users can create multiple presets for different types of components, ensuring that they have the optimal temperature profiles at their fingertips.

Moreover, the WEP 992D-III incorporates digital calibration options allowing for precise adjustments to the soldering temperature and airflow rate. This feature is particularly beneficial for users who require accurate temperature control to prevent overheating components. The intuitive menu functions further simplify this process, providing a user-friendly interface that guides even novice users through calibration without a steep learning curve. Overall, the convenience of the WEP 992D-III’s preset and menu options significantly enhances the soldering experience, making it a go-to choice for professionals and hobbyists alike. As a versatile station, it prioritizes both efficiency and ease of use, ensuring top-quality results for diverse electronic projects.

Exclusive Technical Support and Warranty

The WEP 992D-III 2-in-1 Soldering and Hot Air Rework Station not only excels in performance and versatility but also offers exceptional technical support and warranty services that enhance the overall user experience. When investing in such equipment, the assurance of reliable support can significantly influence the purchasing decision for many customers.

WEP provides an exclusive 1-year technical support service, ensuring that users have access to expert assistance whenever needed. This period allows customers to familiarize themselves with the functionalities of the WEP 992D-III without the fear of encountering insurmountable problems. The technical support team is well-trained to handle inquiries ranging from basic operational questions to more complex troubleshooting scenarios, thus reinforcing user confidence in the product’s capabilities.

In addition to this robust technical support, WEP also offers 24-hour assistance. This feature is particularly beneficial for users who may encounter issues outside of typical business hours, allowing them to resolve problems swiftly and maintain productivity. This level of support indicates WEP’s commitment to customer satisfaction, catering to both novice and experienced users of the soldering and rework station.

The warranty for the WEP 992D-III further complements its appeal. Customers can benefit from affordable replacement components should the need arise. This cost-effectiveness positions the WEP 992D-III as a practical investment; users can easily access necessary parts to extend the longevity of their workstation without incurring substantial expenses. Overall, the combination of dedicated technical support and a sound warranty makes the WEP 992D-III a favorable option for individuals and professionals seeking a reliable soldering and hot air rework solution.

User Reviews and Feedback

The WEP 992D-III 2-in-1 Soldering and Hot Air Rework Station has garnered considerable attention from users within the electronics community. Feedback from a diverse group of hobbyists, professionals, and educators provides a comprehensive overview of their experiences with this versatile device. Overall, the user reviews present a balanced perspective, highlighting both the advantages and shortcomings of the WEP 992D-III.

Many users commend the dual functionality of the WEP Soldering Iron kit, which seamlessly combines soldering and hot air rework capabilities. This feature allows for increased efficiency and convenience, especially for those engaged in electronics repair and soldering projects. Reviewers often note the unit’s versatility as a significant plus, enabling them to undertake a variety of tasks, from basic soldering to more intricate PCB repairs. Additionally, the station’s adjustable temperature control and rapid heat-up times are frequently praised, making it easy for users to achieve optimal results across different materials.

Conversely, some feedback highlights certain drawbacks that potential buyers should consider. A number of users have reported durability concerns after prolonged use, specifically with the hot air gun attachment. Some reviews mention that the nozzle may not remain securely in place, leading to frustration during precision tasks. Furthermore, while the soldering iron frequently receives positive remarks for its performance, a small percentage of users have indicated issues with the iron tip longevity, needing replacements sooner than expected. Despite these criticisms, the vast majority of reviewers express satisfaction with their investment in the WEP 992D-III, often recommending it for its combination of affordability and functionality.

In conclusion, the user feedback surrounding the WEP 992D-III presents a well-rounded view, acknowledging the station’s strengths in versatility and performance, juxtaposed against concerns regarding durability, particularly over time. Potential buyers are advised to weigh these insights carefully when considering this soldering and rework station.

Conclusion: Is the WEP 992D-III Right for You?

In assessing whether the WEP 992D-III 2-in-1 Soldering and Hot Air Rework Station is suitable for your needs, it is essential to weigh its advantages and disadvantages against your specific requirements and circumstances. This versatile station is well-regarded for its dual functionality, which can be particularly beneficial for both hobbyists and professional technicians who work on varied electronic projects. Its reliable soldering capabilities and the integrated hot air rework feature allow for efficient repairs, making it a strong contender in the mid-range market.

However, potential buyers should consider their experience levels with soldering and rework stations. The WEP 992D-III, while user-friendly, may present a slight learning curve for novices who are unfamiliar with the nuances of soldering techniques or hot air rework processes. For seasoned professionals, the station offers precise temperature control and stability that can accommodate more complex projects effectively.

Additionally, project types play a critical role in determining suitability. If your work frequently involves surface-mounted devices or intricate circuit boards that require advanced rework techniques, then this unit aligns well with those needs. Conversely, if most tasks are simple soldering jobs, the versatility of a two-in-one unit may be more than necessary. Lastly, budget considerations cannot be overlooked; the WEP 992D-III is competitively priced, offering a good balance of quality and features in its price range. Therefore, if you are prepared to invest in a reliable tool with multifaceted applications, the WEP 992D-III may indeed be a worthy addition to your toolkit.