Introduction to the WEP 948D III Soldering Station

The WEP 948D III Soldering Station represents a significant advancement in soldering technology, building upon the success of its predecessors. This innovative soldering station integrates modern features that cater to the needs of both professionals and hobbyists in electronics. Its design emphasizes user convenience, precision, and safety, making it an essential tool for anyone involved in electronic assembly, repairs, or prototyping.

One of the key upgrades in the WEP Soldering iron kit is its enhanced temperature control system, which ensures more accurate heat regulation. This feature is particularly important for intricate electronic work, where precise temperature management can prevent damage to sensitive components. Additionally, the station is equipped with an intuitive digital display that allows users to easily monitor and adjust temperature settings, which further aids in effective soldering and desoldering processes.

The ESD-safe characteristic of the WEP 948D III is an essential factor to consider. Electrostatic discharge (ESD) can pose a significant threat to vulnerable electronic parts, leading to malfunctions or failures. By utilizing ESD-safe tools, such as the WEP 948D III, users can mitigate the risks associated with static electricity, safeguarding their projects from potential damage. This feature highlights the station’s suitability for a wide range of applications, from repairing delicate circuit boards to assembling intricate devices.

In addition to its technical advancements, the WEP 948D III emphasizes user comfort through ergonomic design, making it easier to handle during extended use. Overall, the WEP 948D III stands out as a robust and reliable soldering and desoldering solution, tailored for those who value precision, safety, and efficiency in their electronic endeavors.

Key Features of the WEP 948D III

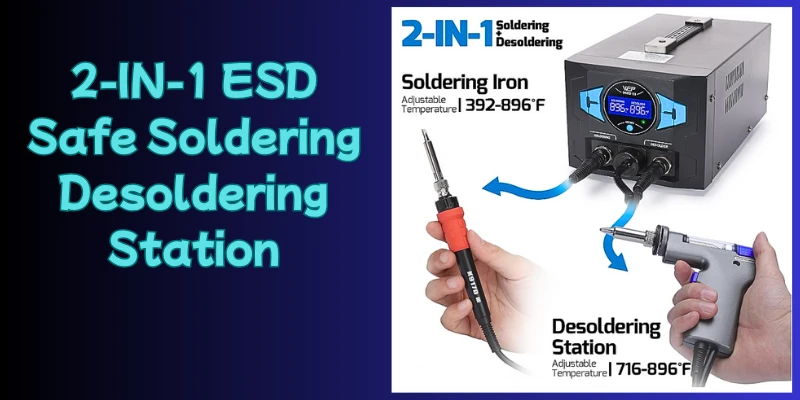

The 2-IN-1 ESD Safe Soldering Station is designed with several standout features that elevate its functionality for both professionals and hobbyists in the electronics field. One of the most significant advantages of this device is its 2-in-1 functionality, which allows users to perform both soldering and desoldering tasks seamlessly. This dual capability not only saves space but also ensures that users have the right tools at their disposal without needing to switch between different devices.

Another critical aspect of the WEP Soldering iron kit is its ESD (Electrostatic Discharge) safety certification. ESD protection is vital in various electronic assembly tasks, as it minimizes the risk of damaging sensitive components. The WEP Soldering iron kit incorporates advanced ESD-safe materials and design features, ensuring that static electricity does not harm the delicate electronics with which users work, making it a trustworthy choice for various applications.

Fast heating is yet another noteworthy feature of this soldering station. The desoldering gun heats up quickly, significantly reducing the waiting time that users often experience with other products. This feature allows for increased efficiency, especially in tasks requiring multiple desoldering actions, facilitating a smoother workflow.

Additionally, the WEP 948D III boasts precision temperature control, enabling users to adjust the soldering and desoldering temperatures according to specific requirements. This level of control ensures optimal results, whether working with intricate components or larger connections. Furthermore, the station includes adjustable soldering tips, accommodating different sizes and shapes to offer flexibility in soldering tasks. Such adaptability enhances the overall user experience, ensuring consistent and effective performance across various projects.

Fast-Heating Desoldering Gun Explained

The WEP 948D III 2-in-1 ESD Safe Soldering and Desoldering Station features a fast-heating desoldering gun that significantly enhances the efficiency of electronic repair and assembly tasks. This innovative tool employs a powerful heating element designed to reach operational temperatures within a remarkably short time frame, which allows for quick solder joint removal without damaging the surrounding components.

At the core of the fast-heating desoldering gun is its advanced thermal technology. This technology ensures rapid heat transfer, enabling the gun to achieve peak temperatures of approximately 350°C in as little as 10 seconds. Compared to traditional desoldering methods, where users often have to wait several minutes for the soldering iron to heat up fully, this feature markedly reduces downtime and enhances productivity in professional settings.

The gun’s design also incorporates a lightweight and ergonomic construction, which promotes comfort during extended use. The comfortable grip reduces hand fatigue, enabling technicians or hobbyists to work on intricate projects for longer periods. Furthermore, the adjustable temperature control allows users to set the desired heat level, accommodating various solder types and component sensitivities. This precise control is crucial, as overheating can lead to damage or failure of delicate electronic parts, a common risk with older desoldering methods.

Furthermore, the efficiency of the fast-heating desoldering gun showcases its superiority over traditional techniques, such as desoldering braid or suction tools. While those methods can be effective, they often require multiple applications or extended timeframes to completely remove solder. In contrast, the fast-heating desoldering gun streamlines the process, providing a singular, efficient solution to remove solder quickly and safely. Overall, the integration of this advanced desoldering technology within the WEP 948D III sets a new standard in workspace efficiency for electronics enthusiasts and professionals alike.

ESD Safe Design: Why It Matters

Electrostatic Discharge (ESD) refers to the transfer of electrical charge between bodies at different electrical potentials. This phenomenon can have detrimental effects on sensitive electronic components, leading to malfunctions, data loss, or complete failure. As such, ESD protection is paramount in environments where electronics are manufactured or repaired. High-stakes settings such as factories or repair workshops are particularly vulnerable, as even a minor discharge can result in significant financial losses and reputational damage. Effective prevention strategies against ESD include the use of specially designed equipment and workspaces.

The significance of utilizing ESD safe equipment cannot be overstated. Tools and stations equipped with ESD protection help to create an environment that minimizes the risk of static electricity buildup and discharge. By dissipating electrical charges safely, these products protect both electronic components and the personnel handling them. In turn, this fosters efficiency and ensures quality control. For instance, vinyl flooring, grounding mats, and ESD safe soldering stations are essential in safeguarding against potential damage caused by static electricity.

The 2-IN-1 ESD Safe Soldering Station is exemplary in this regard. Designed specifically to counteract ESD risks, the WEP 948D III integrates various features that enhance its safety profile. It employs a grounded design, ensuring static electricity is continually directed away from sensitive components. The soldering tips are also designed to conform to ESD safety standards. This focus on ESD-safe design makes the WEP 948D III an ideal choice for both professionals and hobbyists engaged in electronic assembly and repairs, as it not only protects the components but also significantly contributes to maintaining a safe working environment.

Ease of Use and Ergonomics

The WEP 948D III 2-in-1 ESD Safe Soldering and Desoldering Station is designed with user-friendliness at its core, catering to both novices and experienced professionals in the electronics field. One of the standout features of this station is the intuitive layout of its controls, which enables users to navigate settings effortlessly. The prominent display provides clear visibility of temperature settings and operational modes, ensuring users can adjust parameters with precision, ultimately resulting in improved soldering and desoldering efficiency.

Switching between soldering and desoldering functions is seamless, thanks to the clear markings and responsive buttons. Users can easily toggle between modes without having to fumble through complex processes, which saves time and reduces the risk of errors. The quick warm-up time is another aspect that enhances the usability of the WEP Soldering iron kit, allowing users to start their work promptly without unnecessary delays, which is often critical in electronic repair tasks.

In terms of ergonomics, the WEP 948D III does not disappoint. The lightweight design of the soldering iron minimizes hand fatigue during prolonged use, making it an excellent choice for tasks that require attention to detail. Furthermore, the comfortable grip ensures a secure hold, allowing for precision when working on intricate electronics. The thoughtful construction of the station, which includes a robust yet compact station body, means that it occupies minimal workspace while still being stable during operation.

This combination of ease of use and ergonomic design makes the WEP 948D III 2-in-1 ESD Safe Soldering and Desoldering Station an invaluable tool for anyone looking to enhance their workspace. Whether for professional projects or DIY electronics, this station provides a user-centric experience that accommodates varying skill levels while ensuring safety and efficiency.

Comparative Analysis with Other Stations

The WEP 948D III 2-in-1 ESD Safe Soldering and Desoldering Station stands out in a crowded market of soldering stations, providing a unique blend of features that cater to both hobbyists and professionals. When comparing the WEP 948D III to similar soldering stations, several key factors are worth considering: functionality, build quality, temperature control, and overall value for money.

One of the primary strengths of the WEP 948D III is its versatility. Unlike many stations that serve a single purpose, this model combines both soldering and desoldering functions in one unit, saving valuable workspace. It features a built-in heat gun combined with a soldering iron which allows for a wide range of tasks, from soldering delicate electronics to desoldering components with precision. In contrast, other stations such as the Hakko FX-888D or the Weller WHS40 tend to specialize in one aspect, which may not meet all user needs.

In terms of temperature control, the WEP 948D III offers precise adjustments, crucial for various soldering tasks. Its digital LCD display provides users with real-time temperature readings, which enhances the soldering experience by minimizing the risk of overheating components. While competitors may offer similar features, such as the adjustable temperature settings of the X-Tronic 3020-XR3, the WEP model’s ease of use and response time gives it an edge.

However, the WEP 948D III is not without its weaknesses. Some users have reported that the station may lack the durability seen in higher-end models, particularly if subjected to heavy usage in a professional environment. Additionally, while it excels in functionality, the design might not appeal to everyone, as certain other stations provide a more aesthetically pleasing or compact setup. Overall, while the WEP 948D III holds its own against competitors, considerations regarding usage frequency and environment are essential when selecting the best soldering station for your needs.

Maintenance and Care Tips

To ensure the longevity and optimal performance of the WEP 948D III 2-in-1 ESD Safe Soldering and Desoldering Station, regular maintenance and care are essential. Proper upkeep not only prolongs the life of the equipment but also helps maintain the quality of the soldering work performed. One of the first steps in care involves cleaning the soldering iron tip. After each use, it is advisable to wipe the tip with a damp sponge or brass cleaning pad to remove any oxidation and solder residue. This practice helps prevent the buildup of contaminants that can affect the heat transfer efficiency.

Another crucial aspect is the storage of the WEP 948D III when not in use. The soldering tips should be stored in a protective case or a dedicated holder to avoid physical damage and to prevent them from coming into contact with corrosive materials. To further protect the soldering tips, it is recommended to coat them with a small amount of solder before storing the unit. This layer provides a protective barrier against oxidation.

Battery care, if applicable, should not be overlooked. It is important to regularly check and replace batteries as necessary to ensure the station operates effectively. Additionally, avoid leaving the station plugged in for prolonged periods when not in use, as this could potentially shorten the battery’s lifespan and affect overall performance.

Lastly, it is advisable to periodically inspect the cables and connections for signs of wear or damage. Any frayed cables or loose connections should be addressed immediately to prevent safety hazards. By following these maintenance and care tips, users can maximize the efficiency and longevity of their WEP 948D III 2-in-1 ESD Safe Soldering and Desoldering Station.

User Reviews and Feedback

The WEP 948D III 2-in-1 ESD Safe Soldering and Desoldering Station has garnered a considerable amount of attention in the electronics community, and user reviews reveal a mixture of positive sentiments and constructive criticism. Many users appreciate the versatility of the station, lauding its dual functionality that allows for both soldering and desoldering tasks. The ESD safe feature is also frequently mentioned as a benefit, providing peace of mind to those working with sensitive electronic components.

Customers have noted the powerful heating capability of the soldering iron, which heats up quickly and maintains consistent temperatures. This efficiency is particularly beneficial for those who require precision in their work. The lightweight and ergonomic design of the soldering iron has also received praise, making extended use more comfortable. Additionally, the inclusion of various nozzles and tips has been highlighted, offering adaptability for different soldering applications.

However, not all feedback is positive. Some users have reported concerns regarding the durability of components, particularly the soldering iron tip, which they feel may wear down quicker than expected. Additionally, a few reviews mention issues with the temperature control not being as precise as desired, impacting the quality of some soldering jobs. A handful of users have also noted the absence of comprehensive instructions for beginners, which could be daunting for newcomers to soldering and desoldering.

Overall, the WEP 948D III 2-in-1 ESD Safe Soldering and Desoldering Station is generally well-received, boasting features that many users find beneficial. However, potential buyers should weigh the positive aspects against the criticisms to determine if it aligns with their specific needs and expectations in a soldering workspace.

Conclusion and Recommendations

In conclusion, the WEP 948D III 2-in-1 ESD Safe Soldering and Desoldering Station stands out as a comprehensive solution for electronic assembly and repair tasks. Its dual functionality allows users to handle both soldering and desoldering with ease, making it an essential tool for anyone involved in electronics work. The station’s ESD safe design ensures that sensitive electronic components are protected from electrostatic discharge, which is a crucial feature for both hobbyists and professionals.

The adjustable temperature settings permit users to tailor the heat output to specific projects, providing versatility across a range of soldering tasks. Additionally, the ergonomic design enhances user comfort, reducing fatigue during prolonged use. With a robust build quality and reliable performance, this soldering station caters to electronics enthusiasts as well as experienced technicians who require precision and efficiency in their work. The integration of safety features further elevates its value, making it a worthwhile investment.

For those just beginning their journey in electronics or seasoned professionals looking to upgrade their workspace, the WEP 948D III is highly recommended. Hobbyists will appreciate its ease of use and adaptability for various projects, while professionals will benefit from its reliability and precision, ensuring that all electronic components are handled safely and effectively. Overall, the WEP 948D III 2-in-1 soldering and desoldering station embodies an excellent balance of functionality and safety, making it a valuable addition to any electronics toolkit.