Introduction to SN63/PB37 Tin Solder Paste

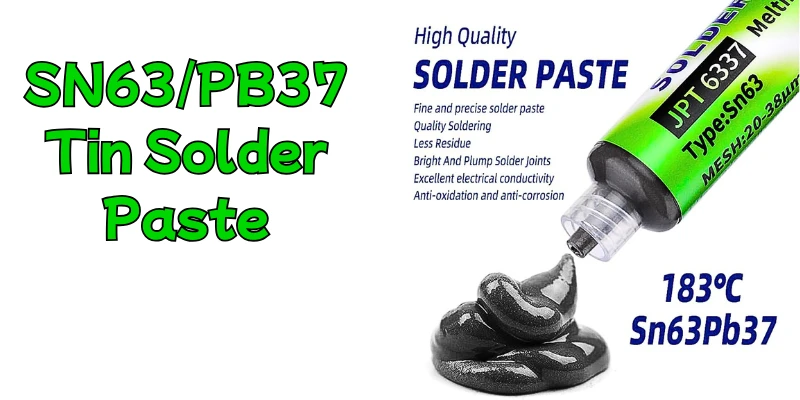

SN63/PB37 tin solder paste is a widely recognized and utilized soldering material in the electronics industry. Composed of 63% tin and 37% lead, this solder paste offers a unique balance that significantly influences its performance and reliability in various applications. The composition of SN63/PB37 Tin Solder Paste is essential, as it not only provides excellent melting characteristics, but also ensures optimal wetting and flow during the soldering process. As a consequence, it contributes to the formation of strong, durable solder joints that are critical to the functionality and longevity of electronic components.

One of the primary reasons for the preference of SN63/PB37 Tin Solder Paste over other solder materials is its low melting point, which is approximately 183 degrees Celsius. This characteristic allows for a gentler soldering process, reducing the risk of damage to heat-sensitive components often found in modern electronic devices. Moreover, myriads of professionals favor SN63/PB37 due to its capability to form reliable connections; this is critical in high-performance electronics where even minor defects can lead to failure.

The solder paste serves not only as an adhesive but also as an electrical conductor, which is inherently vital in any electronic assembly. Its robust performance in various soldering applications demonstrates why it has remained a staple material over the years. With a historical context rooted in the advent of lead-containing solders, SN63/PB37 has evolved, yet it continues to dominate due to its reliability, ease of use, and the quality of the solder joints it produces.

In a market increasingly concerned with performance under stringent standards, SN63/PB37 tin solder paste remains a preferred choice. Its unique blend of tin and lead strikes a balance between mechanical strength and electrical conductivity, making it indispensable in the modern electronics landscape.

Understanding Melting Point and Its Importance

The melting point of solder materials, particularly SN63/PB37 Tin Solder Paste, plays a crucial role in their application in the electronics industry. With a melting point of 183℃, SN63/PB37 solder paste is particularly well-suited for various soldering tasks, primarily due to its optimal thermal characteristics. The significance of this specific melting point cannot be overstated, as it influences the usability and reliability of the solder paste in thermal-sensitive environments. This characteristic directly impacts how solder paste interacts with electronic components during the manufacturing process.

A lower melting point, such as that of SN63/PB37 Tin Solder Paste, provides substantial advantages when working with delicate electronic components. During the soldering phase, components can be susceptible to heat damage, which can lead to performance issues or complete failure. The 183℃ melting point minimizes the risk of overheating, thus reducing the likelihood of damaging heat-sensitive parts. This makes SN63/PB37 Tin Solder Paste an excellent choice for applications involving surface mount devices (SMDs) or fine-pitch components, which often necessitate careful handling and precise thermal management.

Moreover, solder pastes with lower melting points, like SN63/PB37 Tin Solder Paste, facilitate better wetting on substrates, enhancing joint integrity and continuity. The ease of application at this temperature allows the paste to flow smoothly, ensuring thorough coverage and adhesion to both pads and components. This improved flow can contribute to stronger solder joints, which is vital in maintaining the long-term reliability of electronic devices. Additionally, the ability to solder at lower temperatures can lead to reduced thermal stress on surrounding components and substrates, further enhancing overall assembly strength.

Particle Size and Its Role in Soldering

The particle size of solder paste plays a crucial role in determining the overall efficiency and effectiveness of the soldering process. In the context of SN63/PB37 tin solder paste, the particle size typically ranges from 20 to 38 micrometers (µm). This specific particle size range is carefully optimized to enhance various soldering parameters, ensuring that the paste performs at its best.

One of the primary ways in which particle size influences soldering performance is through flow characteristics. Smaller particles tend to provide better flow, allowing the solder paste to spread evenly and fill in small gaps more effectively. This is particularly important for applications in the electronics industry, where components are often closely packed. The ideal particle size enables the solder paste to maintain adequate viscosity, ensuring that it can be applied accurately without excessive runoff or bridging between components.

Furthermore, the particle size also affects the quality of solder joints formed during the reflow process. A well-proportioned mix of particles allows for optimal melting and fusing, resulting in reliable electrical connections. In addition, the specified size aids in the prevention of defects such as voiding, which may compromise joint integrity. Ultimately, utilizing solder paste with appropriate particle size contributes to achieving consistent results in solder joint quality.

For specific applications, choosing the right particle size is essential. For instance, in finer pitch applications where component leads are closely spaced, smaller particle sizes may be advantageous. In contrast, applications involving larger components may benefit from slightly larger particles, ensuring that sufficient solder is available to form solid connections. Selecting SN63/PB37 tin solder paste tailored to the required particle size allows manufacturers to enhance production efficiency while securing high-quality solder joints.

Best Tin Solder Paste SN63/PB37

The best Tin Solder Paste SN63/PB37 is widely trusted by professionals for its excellent reliability, smooth application, and strong soldering performance. With a eutectic composition of 63% tin and 37% lead, this paste provides a low melting point and consistent flow, making it ideal for PCB assembly, rework, and fine-pitch components. Its fast wetting action ensures clean, shiny joints with minimal defects, making it a top choice for hobbyists, technicians, and electronics manufacturers. If you want high-quality results in your soldering projects, SN63/PB37 solder paste remains one of the most dependable options available.

Soldering Flux: Enhancements in Performance

Soldering flux plays a critical role in the performance of SN63/PB37 solder paste, serving both as a cleaning agent and a protective barrier for solder joints during the soldering process. The flux helps to reduce oxidation on metal surfaces, ensuring optimal wetting of the solder material. This is particularly crucial in electronic applications such as printed circuit boards (PCBs), integrated circuits (ICs), ball grid arrays (BGAs), and surface mount devices (SMDs), where reliability and conductivity are paramount.

There are various types of flux used in solder paste, classified primarily into rosin-based, water-soluble, and no-clean varieties. Rosin-based flux offers excellent electrical insulation and solid performance under high-temperature conditions. Its natural properties allow it to remain effective in protecting solder joints during the soldering process. Water-soluble flux, on the other hand, can be easily cleaned after soldering, making it advantageous in specific applications where residue is a concern. No-clean fluxes do not require cleaning, as they leave minimal residue that is generally non-conductive; this characteristic provides added convenience for manufacturers who prioritize efficiency.

The chemical properties of the flux are vital for its effectiveness. The active ingredients in the flux facilitate the removal of oxides and other contaminants that can hinder solder flow and adhesion. By breaking down these barriers, the flux ensures that the solder adheres properly to the surfaces being joined, ultimately enhancing the reliability of the connection. Enhanced wetting capability allows for better joint formation, reducing the risk of cold solder joints and ensuring effective electrical pathways.

In conclusion, the inclusion of high-quality soldering flux in SN63/PB37 solder paste significantly enhances the overall performance during the soldering process. By choosing the appropriate type of flux and understanding its properties, manufacturers can achieve reliable connections in complex electronic assemblies.

Applications in Electronics: PCB, IC, BGA, and SMD Repair

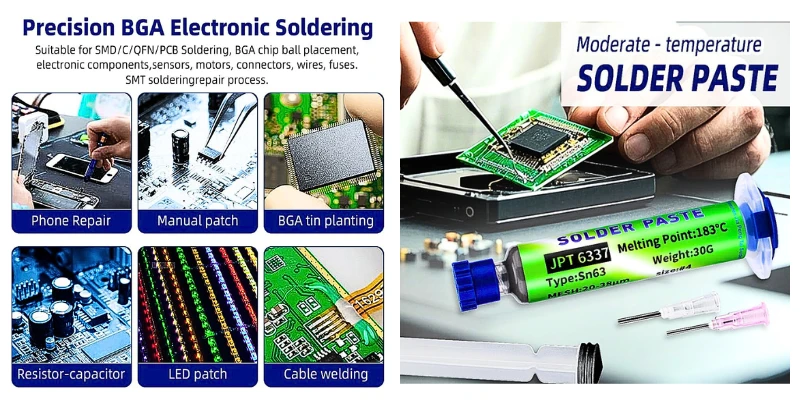

SN63/PB37 solder paste is widely favored in the electronics manufacturing industry due to its superior properties that enhance the soldering process. One of the primary applications of this solder paste is in printed circuit board (PCB) assembly. The eutectic composition of SN63/PB37 Tin Solder Paste allows for excellent wetting and flow, which is crucial in ensuring reliable connections between components and the PCB substrate. Its lower melting point facilitates rapid soldering cycles, thereby optimizing production efficiency without compromising quality.

In addition to PCB assembly, SN63/PB37 Tin Solder Paste is extensively used in the repair of integrated circuits (ICs). The ability to restore connections and rectify faults in ICs without damaging sensitive components is critical for maintaining functionality. When combined with appropriate fluxing agents, this solder paste helps in removing oxidization and ensures that the solder adheres effectively during the rework process. Professionals in the field often rely on case studies highlighting successful IC repairs using SN63/PB37, demonstrating its efficacy in real-world settings.

Another significant application area for SN63/PB37 Tin Solder Paste is in ball grid array (BGA) soldering. With the increasing complexity and miniaturization of electronic devices, BGA components are prevalent due to their efficiency in thermal and electrical performance. The characteristics of SN63/PB37 solder paste enable effective solder joint formation in BGA applications, which is essential for maintaining signal integrity. Furthermore, surface mount device (SMD) repairs benefit from this solder paste as well, given its ability to accommodate the fine pitch of modern SMD components. The versatility of SN63/PB37 in these diverse applications cements its standing as a go-to solution in the electronics industry, showcasing its importance in creating reliable devices.

Advantages of Using SN63/PB37 Tin Solder Paste

The SN63/PB37 tin solder paste is widely recognized for its unique combination of advantageous properties that cater to a variety of soldering applications. One of the primary benefits of this solder paste is its exceptional solderability. The 63% tin and 37% lead composition creates a low melting point, facilitating easier flow during the soldering process. This low melting point not only enhances the paste’s ability to adhere to different substrates but also minimizes thermal stress on sensitive components, making it a preferred choice among professionals in electronics manufacturing and DIY enthusiasts alike.

Reliability is another significant advantage offered by SN63/PB37 Tin Solder Paste. The characteristics of this alloy contribute to robust joints that withstand mechanical and thermal shocks, thereby ensuring durability in finished products. The paste’s ability to form consistent and reliable solder joints is critical, especially in applications where long-term stability is required. As a result, this solder paste is often utilized in high-performance and mission-critical electronic assemblies, where failure is not an option.

Ease of use is a notable trait that also cannot be overlooked. SN63/PB37 Tin Solder Paste is readily available in various formulations, allowing users to choose the most suitable viscosity and flux type for their specific project needs. This adaptability makes the paste not just accessible for experienced technicians but also manageable for novice users engaged in hobbyist projects. Additionally, employing SN63/PB37 Tin Solder Paste can lead to potential cost savings. Its efficient flow behavior reduces the amount of paste needed per joint, which can result in reduced materials costs over time. Furthermore, by streamlining the soldering process and minimizing repair work, users can achieve greater efficiencies in their workflows, contributing positively to overall project economics.

Top Uses of Sn63 Pb37 Tin Solder Paste in Electronics

The Sn63 Pb37 tin solder paste uses extend across a wide range of electronics applications due to its excellent performance, reliability, and ease of use. With a eutectic composition of 63% tin and 37% lead, this solder paste offers a low melting point, allowing it to flow smoothly and create strong, clean joints with minimal thermal stress on sensitive components.

These properties make it ideal for PCB assembly, rework, fine-pitch components, and various precision soldering tasks. Because the alloy forms durable and consistent joints, it is widely used in high-performance electronics, mission-critical devices, and DIY repair projects. Its availability in different flux types and viscosities makes it adaptable for both professionals and hobbyists, making SN63/PB37 one of the most trusted options for diverse soldering needs.

Multi-pack Options: Why Choose a 5 Pack?

When it comes to selecting solder paste, particularly SN63/PB37 Tin Solder Paste, opting for a 5-pack format can offer several advantages that enhance both convenience and efficiency. Firstly, purchasing solder paste in a 5-pack allows users to have a readily available supply on hand, reducing the need for frequent reorders. This is particularly beneficial for professionals and hobbyists who engage in multiple projects or require solder paste on a continuous basis. With a 5-pack, there is a lower risk of running out of materials during critical phases of any project.

Furthermore, storing multiple packs of solder paste in a single purchase can lead to improved organization. When all the solder paste is kept together, it minimizes the clutter associated with various projects. Users can easily track their inventory and avoid the scenario where one project is held up due to a shortage of solder paste, making overall workflow more efficient.

Cost-effectiveness is another significant benefit of choosing a 5-pack. Providers often give incentives such as discounts or better pricing per unit when bought in bulk. This can lead to substantial savings over time, especially for those who rely heavily on solder paste for electronic assemblies or repairs. Additionally, a multi-pack option allows users to experiment with different projects without the concern of exhausting their supply too quickly.

Moreover, the characteristics of SN63/PB37 Tin Solder Paste make it suitable for a variety of applications. By having multiple packs available, users can effectively accommodate diverse project requirements, ranging from small repairs to large-scale assembly work. This versatility ensures that one pack does not interfere with the completion of other tasks, thus improving productivity. Therefore, choosing to purchase a 5-pack of solder paste not only provides convenience but also contributes to an overall enhanced experience.

Best Practices for Using SN63/PB37 Solder Paste

To make the most of SN63/PB37 solder paste, adhering to a set of best practices is crucial for ensuring optimal soldering results. First and foremost, proper storage is essential. The solder paste should be kept in a cool, dry environment, ideally at temperatures between 0°C to 10°C. This helps to prolong its shelf life and maintain its viscosity, thereby enhancing its performance during application. Once the paste is opened, it should be used promptly and any unused portion sealed tightly to prevent contamination and drying out.

When it comes to application methods, using a stencil is one of the most effective techniques for applying solder paste evenly onto the printed circuit board (PCB). This ensures that the perfect amount of paste is deposited on each pad, resulting in more consistent solder joints. Additionally, ensure that the stencil is clean and free from debris to avoid any potential complications during the printing process. Once applied, the paste needs to be inspected to confirm that no voids or misprints exist, as these can adversely affect solder joint reliability.

Another important practice involves the reflow process. The temperature profile must be correctly established, as overheating can lead to the oxidation of solder particles, while insufficient heat may result in inadequate melting. Conducting a preheating stage before the actual reflow can promote even heat distribution, helping in achieving the ideal solder joint quality. It is also advisable to attend to common pitfalls, such as applying too much solder paste or allowing extended exposure to air, both of which can lead to undesirable solder results.

Fostering a clean working environment while regularly maintaining tools and equipment will further assist in maximizing the performance of SN63/PB37 Tin Solder Paste. Such diligence in practice contributes significantly to the overall effectiveness and reliability of soldering operations.

Conclusion: The Future of Tin Solder Paste in Electronics

The SN63/PB37 tin solder paste has long been a cornerstone in the electronics manufacturing industry due to its reliable properties and ease of use. Its blend of 63% tin and 37% lead provides a melting point that allows for efficient soldering processes, making it a preferred choice for many applications. However, as the industry evolves, so does the conversation around solder materials, especially with the increasing focus on sustainability and safety regulations.

Future trends in soldering materials are leaning towards lead-free alternatives, which aim to mitigate the health and environmental concerns associated with lead use. Various compositions, such as SAC (tin-silver-copper) alloys, are being developed and adopted. These alternatives strive to provide similar or superior mechanical properties while adhering to stringent RoHS (Restriction of Hazardous Substances) directives. As a result, solder paste manufacturers are innovating to meet the demands of modern electronics while ensuring compliance with evolving industry standards.

Furthermore, technological advancements in manufacturing processes and materials science are likely to influence the use and formulation of solder pastes in the future. Enhanced performance characteristics, including lower voiding rates and improved thermal fatigue resistance, may become critical as electronic devices become more compact and complex. These developments are not only shaping current practices but are also setting the precedent for future applications in various sectors, including consumer electronics, automotive, and aerospace industries.

In conclusion, while SN63/PB37 solder paste has established itself as a staple in electronics, the industry’s shift towards greener alternatives and innovative soldering technologies will usher in a new era of materials. The interplay between tradition and innovation will define the landscape of soldering materials in the years to come, highlighting the importance of adaptability in the face of change.