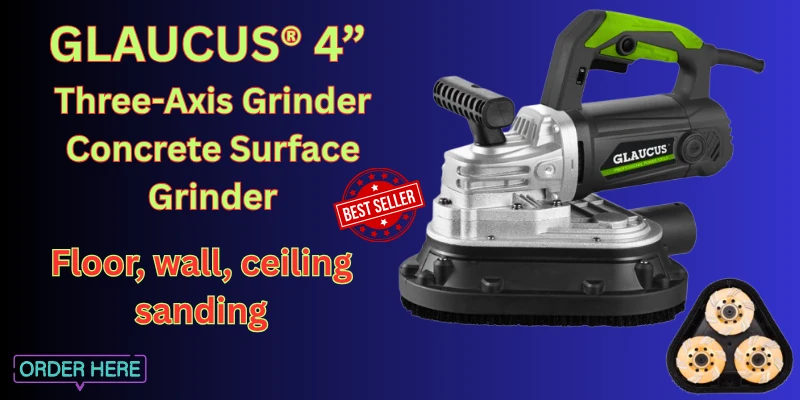

Introduction to the GLAUCUS Concrete Surface Grinder

The Glaucus® 4” three-axis grinder is a notable advancement in the field of concrete surface preparation, designed to meet the diverse needs of professionals who require efficient and effective surface finishing. This grinder boasts an innovative three-axis design that allows for unparalleled maneuverability across different surfaces such as floors, walls, and ceilings. Its unique capacity to adapt to various applications makes it a versatile tool for contractors and surface preparation specialists.

Featuring a robust construction, the GLAUCUS Concrete Surface Grinder is equipped with a powerful motor that provides high torque, ensuring optimal performance during grinding tasks. The design emphasizes user comfort and safety, featuring ergonomic handles that reduce operator fatigue during extended use. Its lightweight body further enhances portability, enabling users to transport it easily to job sites without cumbersome effort.

One of the standout characteristics of the GLAUCUS 4” Concrete Surface Grinder is its advanced dust extraction capability, which significantly reduces airborne particulates during operation. This functionality not only improves the work environment but also ensures compliance with industry safety standards. The grinder accommodates a wide range of diamond abrasive pads, allowing users to tailor their tools to specific concrete surfaces and desired finishes.

The evolution of concrete grinders has led to increasingly sophisticated designs, yet the Glaucus® stands out with its combination of versatility and precision. Unlike traditional grinders that may be limited to horizontal applications, this three-axis grinder excels in vertical and overhead projects as well. Such adaptability makes the Glaucus® a compelling choice for any concrete surface preparation task, setting a new standard for efficiency and effectiveness in the industry.

Key Features and Benefits

The GLAUCUS Concrete Surface Grinder stands out in the realm of concrete surface preparation due to its multifaceted features and robust performance. Central to its design is the innovative three-axis grinding capability, which allows for superior maneuverability and enhanced grinding efficiency. This feature enables the grinder to perform with precision across a variety of surfaces, ensuring an even finish that meets professional standards.

One of the notable attributes of the GLAUCUS 4” Concrete Surface Grinder is its compact design. Weighing in at just the right balance, it is lightweight enough for easy handling while still delivering the power required for rigorous tasks. This combination of portability and robustness makes the grinder ideal for both indoor and outdoor applications, whether in tight spaces or more expansive environments.

Furthermore, the ease of use is a paramount benefit. Designed with user-friendly controls, operators can adjust settings with minimal effort, allowing for a seamless transition between different grinding tasks. This is particularly beneficial for professionals who require versatility in their tools, as the Glaucus® grinder can cater to various surface types and conditions.

Durability is another key attribute, as the GLAUCUS 4” Concrete Surface Grinder is constructed from high-quality materials designed to withstand the rigors of frequent use. It is engineered to resist wear and tear, ensuring longevity and sustained performance over time. In addition to its robust construction, operators can expect improved efficiency compared to traditional grinders, leading to time savings on projects that require concrete surface preparation.

Ultimately, the Glaucus® 4” Three-Axis Grinder not only provides advanced capabilities but also enhances user experience through its thoughtful design features. With precise sanding, adaptability, and durability, it is an invaluable tool for both professional contractors and DIY enthusiasts in the construction industry.

Applications of the GLAUCUS Concrete Surface Grinder

The Glaucus grinder has garnered attention for its incredible versatility and efficiency across a range of concrete surface preparation tasks. This innovative tool excels at sanding concrete floors, walls, and ceilings, making it an essential asset for both commercial and residential projects. Its compact design allows for easy maneuverability, which is particularly beneficial when working in tighter spaces or on vertical surfaces.

One of the primary applications of the GLAUCUS Concrete Surface Grinder is in the preparation of concrete floors for finishing processes. Whether it involves removing old coatings, smoothing uneven surfaces, or achieving a polished finish, the grinder’s advanced three-axis technology ensures optimal results. The grinder’s ability to adapt to various angles makes it especially effective on sloped or irregularly shaped surfaces, significantly reducing the time and effort required for floor preparation.

In addition to floor applications, the GLAUCUS Concrete Surface Grinder is ideal for wall sanding. Contractors can utilize this tool to effectively remove imperfections, such as rough patches or excess material, ensuring that the surface is smooth and ready for painting or sealing. Its lightweight design minimizes fatigue during extended use, thus promoting efficiency and precision even on vertical applications.

Furthermore, the grinder’s utility extends to ceiling treatments, where its effectiveness can play a crucial role in renovation or restoration projects. Whether it’s for residential spaces or larger commercial clients, the Glaucus grinder operates effectively while offering a consistent finish across various concrete substrates.

In summary, the Glaucus® 4” three-axis grinder proves to be an invaluable tool for diverse applications in concrete surface preparation, catering to the needs of both commercial and residential sectors. Its efficiency, adaptability, and precision make it a top choice for contractors seeking high-quality results in their projects.

How to Operate the GLAUCUS 4” Concrete Surface Grinder Effectively

Utilizing the GLAUCUS Concrete Surface Grinder for concrete surface preparation requires careful attention to safety and technique to achieve optimal results. To begin, ensure that you wear appropriate personal protective equipment (PPE), including safety goggles, a dust mask, and gloves. This gear will help protect you from harmful dust and debris produced during the grinding process.

Once you have your PPE in place, gather the necessary materials. The Glaucus grinder is versatile, so select the right diamond blade or grinding pad suitable for the specific task you are undertaking. Review the manufacturer’s guidelines for recommendations on the best abrasive tools for concrete surfaces.

To start the grinding procedure, plug in the grinder and allow it to reach full speed before making contact with the concrete. A slow, steady pace will yield the best results; do not rush the process. Position the grinder at a comfortable angle, typically around 30 degrees, while applying light pressure to the surface. This approach ensures that the diamond abrasives effectively remove material without damaging the substrate.

Employ a consistent back-and-forth motion while guiding the grinder across the surface, allowing the tool to do the work. Make sure to frequently check your progress to avoid over-grinding any particular area. Depending on your grinding needs, you may need to change pads or blades as different materials will require varying levels of abrasiveness and grit.

For optimal cleanliness and visibility during the grinding process, consider using a vacuum attachment compatible with the Glaucus grinder. This feature helps capture dust and debris, contributing to a healthier working environment. Lastly, once you have achieved the desired finish, clean your workspace and perform a thorough maintenance check on the grinder to prolong its lifespan.

Maintenance and Care for Longevity

The longevity of the Glaucus grinder heavily relies on regular maintenance and proper care. Adopting best practices in maintaining this essential concrete surface preparation tool can significantly enhance its performance and lifespan.

First and foremost, cleaning procedures should be implemented after each use of the grinder. This process involves removing dust and debris that accumulate on the machine’s exterior and grinding pads. A damp cloth can effectively wipe down the body of the unit, while a soft brush or vacuum can help eliminate residual concrete and dust from the grinding area. This step not only preserves the machine’s functionality but also keeps it aesthetically appealing.

Changing grinding pads is another crucial aspect of maintenance. As the pads wear down, they can impact the grinder’s efficiency and the quality of surface preparation. It is advisable to inspect the condition of the pads regularly and replace them at the first signs of wear. Depending on the frequency of use and the materials being worked on, changing the pads every few uses may be necessary to ensure optimal performance.

Furthermore, users should familiarize themselves with troubleshooting common issues. If the grinder is producing excessive vibrations or if there is a noticeable drop in speed, these could be indicators of underlying problems requiring attention. Consulting the manufacturer’s manual for guidance on troubleshooting can help users address issues promptly, preventing minor concerns from escalating into more significant repairs.

Lastly, proper storage practices contribute to the grinder’s longevity. Storing the Glaucus grinder in a dry and secure place, away from moisture and extreme temperatures, helps prevent corrosion and mechanical failures. Additionally, ensuring that the machine is stored in an upright position can further protect the grinding head and overall structure.

Comparison with Other Concrete Grinders

The Glaucus® 4” Three-Axis Grinder stands out in the competitive landscape of concrete surface preparation equipment. To understand its advantages, it is beneficial to compare it with other concrete grinders available in the market. Performance is a critical factor; the Glaucus grinder incorporates a unique three-axis design that offers superior maneuverability and efficiency. In contrast, many conventional grinders feature a more traditional two-axis system, which can limit the accessibility to tight corners and intricate surfaces.

When evaluating features, the Glaucus grinder showcases a lightweight yet robust build, making it suitable for prolonged use without causing operator fatigue. Furthermore, it possesses effective dust control mechanisms, which are essential for maintaining a clean work environment. Many other grinders, particularly those at a lower price point, tend to neglect dust management, thus compromising user safety and comfort.

Pricing also plays a significant role in the decision-making process. The Glaucus grinder, while priced higher than some of its competitors, offers superior durability and technology. This investment often leads to lower long-term costs, as users experience fewer repairs and replacements over time. In contrast, budget grinders may seem appealing initially but frequently incur additional costs due to their subpar performance and shorter lifespan.

Use cases for the Glaucus grinder are wide-ranging; professionals appreciate its versatility for both surface preparation and finishing tasks. Other grinders might excel in specific applications but fall short when versatility is required. Overall, the Glaucus® 4” Three-Axis Grinder not only meets but often exceeds the benchmarks set by other concrete surface grinders, making it a commendable choice for both seasoned contractors and DIY enthusiasts.

Customer Reviews and Testimonials

The GLAUCUS 4” Concrete Surface Grinder has garnered attention in the concrete surface preparation industry, prompting numerous users to share their experiences. Feedback from customers showcases a range of opinions, highlighting both the benefits and the challenges associated with this innovative tool.

Many customers praise the grinder for its efficiency and ease of use. Users have noted that the three-axis design allows for better maneuverability and precision, significantly improving their workflow. One customer shared, “The GLAUCUS 4” Concrete Surface Grinder adapts easily to various surfaces, making my concrete preparation projects quicker and requiring less physical effort.” This sentiment is echoed by others who appreciate the ergonomic design, which reduces user fatigue during extended periods of operation.

In addition to user-friendly features, the grinding performance has received commendations. Several testimonials highlight the machine’s effectiveness in removing coatings and achieving a smooth finish. A satisfied customer remarked, “This grinder outperforms others I have used in the past. I was able to complete the job in half the time, achieving a surface that was perfectly prepared for the next stage.” Such accounts emphasize the product’s potential to enhance productivity on the job site.

However, the feedback is not without its criticisms. Some users have reported issues with the grinder’s durability, indicating that after extensive use, certain components may require replacement. One customer mentioned, “While the performance is outstanding, I’ve had to replace the pads more often than I anticipated.” Recognizing these experiences is vital for prospective buyers to understand the product’s limitations and strengths.

This collection of reviews illustrates the Glaucus® 4” Three-Axis Grinder as a game-changing tool for concrete surface preparation, yet also highlights areas for potential improvement. Overall, customer testimonials provide valuable insights into the diverse applications and performance of this grinder, making it a noteworthy option for industry professionals.

Frequently Asked Questions

The Glaucus® 4” Three-Axis Grinder has garnered significant attention in the construction and renovation sectors due to its innovative design and functionality. Below, we address some of the most frequently asked questions to provide potential buyers with essential information.

1. Is the Glaucus® 4” grinder compatible with different grinding pads?

Yes, the Glaucus grinder is designed for versatility, allowing it to be compatible with various grinding pads. This ensures that users can select the best grinding pad for their specific surface preparation needs, whether it involves aggressive grinding or fine polishing. The grinder accommodates different attachment types, making it easier to switch between tasks and ensuring optimum performance for different materials.

2. What warranty does the Glaucus® 4” grinder come with?

The manufacturer offers a comprehensive warranty for the Glaucus® 4” Three-Axis Grinder, typically covering defects in materials and workmanship. The specific duration of the warranty may vary, so it is advisable for buyers to check the details provided upon purchase. This warranty signifies the company’s confidence in the product’s durability and encourages customers to explore its features without hesitation.

3. Are there safety features included in the design of the Glaucus® grinder?

Absolutely, safety is paramount in the design of the Glaucus grinder . This model includes several essential safety features such as an automatic shut-off system when overheating occurs, ensuring user protection during operation. Additionally, it encompasses an ergonomic handle and anti-vibration technology to enhance user comfort and minimize fatigue. These thoughtful design elements enhance the overall usability of the grinder while prioritizing operator safety.

4. How easy is it to operate the Glaucus® 4” grinder?

The operation of the Glaucus grinder has been engineered with user-friendliness in mind. Its lightweight structure and intuitive controls allow for easy maneuvering across various surfaces. Users can quickly familiarize themselves with its features, minimizing the learning curve typically associated with new machinery. This accessibility makes it an ideal choice for both professionals and DIY enthusiasts.

Conclusion: Is the Glaucus® 4” Grinder Right for You?

In evaluating the Glaucus® 4” Three-Axis Grinder, it becomes evident that this innovative tool offers a blend of efficiency, versatility, and value that is highly appealing to both professionals and DIY enthusiasts involved in concrete surface preparation. One of the primary advantages of this grinder is its ability to handle a variety of tasks, including grinding, polishing, and preparing concrete surfaces for further treatment. This multifunctionality means that users can streamline their processes, reducing the need for multiple tools and thus saving time and costs in the long run.

Moreover, the grinder’s three-axis design significantly enhances its performance by allowing for better control and precision during operation. This feature is crucial for achieving optimal results, especially in projects that require intricate surface preparation. Users have reported noticeable improvements in efficiency, being able to complete tasks more quickly compared to traditional methods. This efficiency is coupled with a user-friendly design that accommodates both seasoned professionals and novices, ensuring that anyone can effectively utilize the Glaucus grinder.

Cost-effectiveness is another aspect worth considering when deciding if the Glaucus grinder aligns with your needs. With its durability and high-performance capabilities, investing in this grinder may yield a favorable return over its lifespan. For those contemplating enhancements to their concrete surface preparation toolkit, the Glaucus grinder represents a robust option. Ultimately, assessing your specific requirements and the types of projects you frequently undertake will guide you in determining if the Glaucus grinder is indeed the right fit for you. Ensuring that your tools support your work effectively can make a significant difference in project outcomes and overall satisfaction.