Introduction to the Weldpro 200A TIG Welder

The Weldpro 200A AC/DC Aluminum TIG Welder stands out as a significant tool in the welding industry, particularly for its adeptness at welding aluminum. Its dual functionalities allow users to perform both AC and DC welding, making it suitable for a variety of metals and applications. This versatility makes the welder ideal not only for professionals in industrial settings but also for do-it-yourself enthusiasts looking to tackle home projects effectively.

One of the key features of the weldpro mig welder is its adjustable pulse feature, which optimizes the welding arc for improved control and precision. This pulsating functionality is particularly beneficial when working with thinner materials, as it minimizes the risk of burn-through and enables fine-tuning of weld beads. Additionally, the welder comes equipped with a CK 17 Worldwide Superflex TIG Torch, known for its flexibility and comfort during prolonged use. This torch enhances maneuverability, making it easier for welders to access tight spaces or perform intricate welds.

The Weldpro 200A kit includes various essential components, which contribute to its comprehensive usability. Included in the package are tungsten electrodes, gas cups, collets, and a foot pedal for remote amperage control, allowing users to achieve the desired welding output effortlessly. Furthermore, the machine’s user-friendly interface, featuring digital displays and straightforward controls, simplifies the welding process for novices while still offering advanced adjustments for expert welders.

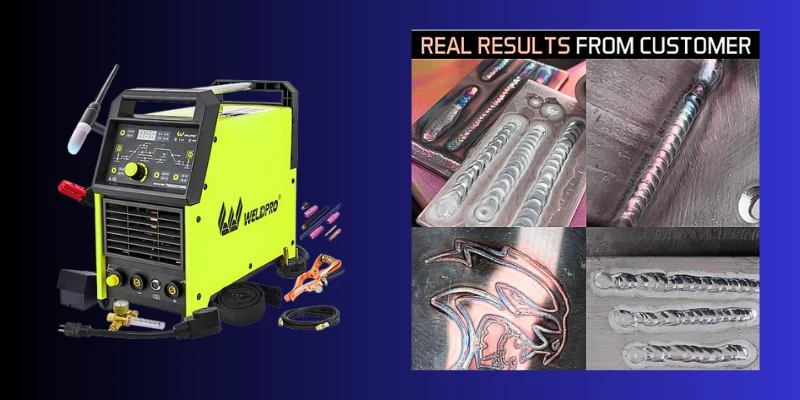

In observing the market trends and user feedback, the Weldpro 200A AC/DC Aluminum TIG Welder emerges as a favored choice, appreciated for its reliable performance and exceptional versatility in welding applications. Its design and included tools foster an effective welding experience, making it a commendable option for both professionals and hobbyists alike.

Technical Specifications of the weldpro mig welder

The Weldpro 200A AC/DC Aluminum TIG Welder is designed with advanced specifications that cater to a diverse range of welding applications, particularly in aluminum welding. One of its standout features is its dual voltage functionality, allowing operation at both 110V and 220V. This versatility provides users with the flexibility to work in various environments, from home garages to professional workshops. The welder seamlessly switches between voltages without compromising performance, making it accessible for welders at different expertise levels.

In terms of amperage capabilities, the weldpro mig welder boasts impressive output levels ranging from 10A to 200A. This broad range allows for precise control over the welding process, enabling users to tackle projects that require both fine detail and robust joinery. Whether performing low-heat operations on thin materials or executing high-heat welds on thicker stock, this welder meets the demands without difficulty.

Another critical aspect of the weldpro mig welder is its incorporation of advanced digital inverter technology. This feature not only enhances performance by providing a stable and consistent output but also improves energy efficiency. Digital inverters reduce the overall power consumption compared to traditional welders, making them more sustainable options in the long run. Furthermore, the welder weighs approximately 50 pounds and has dimensions of 22 x 10 x 18 inches, providing a portable yet sturdy design. The power requirements are aligned with its dual voltage capabilities, requiring a dedicated circuit to ensure safety and optimal functionality.

Overall, the technical specifications of the Weldpro 200A AC/DC Aluminum TIG Welder highlight its capacity to deliver precision and reliability, making it an excellent choice for both amateur and skilled welders alike.

Understanding AC/DC Welding: Benefits and Applications

AC (Alternating Current) and DC (Direct Current) welding techniques each possess distinct advantages that cater to different materials and applications within various industries. One of the primary benefits of AC welding is its capability to produce a strong weld on non-ferrous metals, particularly aluminum. The alternating nature of AC allows it to penetrate aluminum effectively and produces less heat than DC. This feature is vital when welding thinner materials, where excessive heat can lead to warping or melting.

Conversely, DC welding is particularly advantageous for ferrous metals, such as steel and stainless steel. With direct current, the arc is steadier and easier to control, which is essential for achieving high-quality welds on these materials. The constant polarity of DC helps to produce a cleaner, more stable weld with better penetration, making it a preferred choice for many industrial applications.

The versatility of both AC and DC welding techniques makes them appropriate for a wide range of industries. In automotive manufacturing, for example, AC welding is often employed for aluminum components in vehicle bodies, offering durability while minimizing heat distortion. Meanwhile, DC welding finds its applications in fabricating structural components, as the controlled arc leads to better strength and reliability of the required joints.

Moreover, fabrication shops commonly utilize both techniques, depending on the materials at hand. AC welding can effectively tackle aluminum frames or other non-ferrous structures, while DC welding can streamline the production of stainless steel fixtures or tools. In essence, understanding the complementary nature of AC and DC welding is pivotal for welders aiming to optimize their processes and outcomes.

Pulse Functionality: Enhancing Welding Precision

The pulse functionality of the Weldpro 200A AC/DC Aluminum TIG Welder represents a significant advancement in weld quality and control. By alternating the welding current between a predefined high and low level, pulse welding allows for greater manipulation of the molten pool. This method is particularly advantageous in applications where precision is paramount, such as in the welding of thin materials or in complex, intricate projects.

A primary benefit of the pulse feature is its ability to reduce heat input during the welding process. When working with thin metals, excess heat can lead to warping or burn-through, which compromises the integrity of the weld. The pulse function mitigates this risk by minimizing heat accumulation, ensuring that the material retains its original properties and preventing overheating. Moreover, this reduced heat input can also contribute to a decrease in the amount of filler material required, fostering efficiency without sacrificing quality.

Enhanced control over the molten pool is another crucial aspect of pulse welding. With the ability to adjust the duty cycle and frequency, welders can tailor their approach to suit the specific requirements of their project. This fine-tuning allows for meticulous control over bead placement, penetration depth, and overall weld appearance. For applications demanding intricate patterns or delicate joins, such as in artistic metalwork or high-precision assemblies, this enhanced control becomes indispensable.

In conclusion, the pulse functionality of the Weldpro 200A AC/DC Aluminum TIG Welder significantly enhances welding precision, making it an optimal choice for professionals seeking superior results. With its ability to reduce heat input and improve control over the molten pool, this feature not only promotes quality workmanship but also elevates the welder’s capabilities in tackling various projects.

Features of the CK 17 Worldwide Superflex TIG Torch

The CK 17 Worldwide Superflex TIG Torch is a notable addition to the Weldpro 200A AC/DC Aluminum TIG Welder, designed to enhance the overall welding experience. A key feature of this torch is its flexible and lightweight design, which allows for increased maneuverability during welding tasks. This flexibility is essential for reaching difficult positions and providing greater control in various welding scenarios. The Superflex feature significantly reduces fatigue during extended welding sessions, making it an ideal choice for both professional welders and hobbyists.

Moreover, the CK 17’s ergonomic grip further enhances usability. The torch is crafted with a comfortable handle that not only improves grip but also minimizes hand strain, allowing users to work more efficiently for longer periods. The thoughtful design elements ensure that welders can maintain precision and control, crucial for achieving high-quality welds. This ergonomic consideration is especially beneficial when performing intricate tasks or when working in tightly confined spaces.

The CK 17 Worldwide Superflex TIG Torch is compatible with various electrode sizes, allowing users to choose and switch between different tungsten electrodes according to the specific application. This versatility is crucial in a wide range of welding projects, from thin sheets of aluminum to thicker materials. By accommodating various sizes, the torch can adapt to diverse welding needs, thereby ensuring optimal performance and quality, no matter the challenge at hand. This feature enhances the overall effectiveness of the Welder, providing users with the tools necessary to produce clean and precise welds consistently.

User Experience: Setup and Operation

When it comes to the Weldpro 200A AC/DC Aluminum TIG Welder with Pulse CK 17 Worldwide Superflex TIG Torch, user feedback highlights a generally favorable experience regarding setup and operation. Many users have reported that the initial assembly of the welder is straightforward, aided by the well-organized user manual. This manual, which comes with detailed diagrams and clearly written instructions, plays a significant role in facilitating a smooth setup process.

Upon unpacking, most users found that they could begin the setup without unnecessary delays. The welder is designed with user-friendliness in mind, and many users appreciated the intuitive layout of the controls and interface. The knobs, buttons, and switches are easily accessible and labeled, allowing for quick adjustments. Users noted that the dial settings for welding amperage, frequency, and pulse duration are conveniently positioned, making them simple to adjust as needed during operation. This was particularly beneficial for those new to TIG welding, as they could maneuver through the controls without feeling overwhelmed.

Moreover, initial performance adjustments are crucial for achieving optimal results. Several users emphasized the importance of properly calibrating the welder for different materials and thicknesses, which the manual adequately addresses. As users became more familiar with the welder, they expressed that the ability to customize settings led to impressive results, especially when working on aluminum projects. Overall, the setup and operation of the weldpro mig welder is deemed efficient and user-friendly, making it a suitable choice for both beginners and seasoned welders alike.

Safety Features and Best Practices

The Weldpro 200A AC/DC Aluminum TIG Welder is equipped with several essential safety features designed to protect users during operation. One of the most significant features is the thermal overload protection system. This mechanism automatically shuts down the welder when internal temperatures exceed safe limits, thus preventing potential damage to the unit and reducing the risk of fire hazards. Additionally, the welder includes circuit protection, which safeguards the welder’s circuitry against power surges and short circuits, further enhancing operational safety.

In addition to these built-in features, adhering to best practices while using the weldpro mig welder is crucial for ensuring not just personal safety but also achieving optimal welding results. First and foremost, users should don appropriate personal protective equipment (PPE), including a welding helmet with proper shade, gloves resistant to heat and sparks, and protective clothing. These items provide essential protection against arcs, sparks, and potential burns.

Proper ventilation is another safety consideration. When welding, ensure the work area is well-ventilated to dissipate fumes and gases that can be harmful if inhaled. In confined spaces, using exhaust fans or respirators may be necessary to maintain air quality. Furthermore, always inspect the work area for flammable materials before starting the welding process. Keeping a fire extinguisher nearby is also advisable.

Finally, understanding and following the operational guidelines set forth in the weldpro mig welder user manual is critical for safe operation. This includes recognizing the welder’s limits and appropriate settings for various materials. By integrating these safety features and adhering to best practices, users can minimize risks while maximizing the efficacy of their welding projects.

Warranty and Customer Support

When investing in a welding machine, the warranty is a crucial factor to consider, as it can provide peace of mind to the buyer. The Weldpro 200A AC/DC Aluminum TIG Welder comes with a comprehensive three-year warranty that covers defects in materials and workmanship. This warranty signifies the manufacturer’s confidence in the quality and durability of their product, ensuring that customers have a safeguard against potential manufacturing flaws. Buyers will appreciate the assurance that, in the unlikely event of a malfunction, they will have recourse for repairs or replacements without incurring additional expenses.

Weldpro’s warranty is not just a statement; it speaks volumes about the company’s commitment to customer satisfaction. By covering critical components of the welder for three years, Weldpro allows its consumers to focus on their welding projects without the looming concern of unexpected repair costs. This extensive coverage highlights the significance of warranties in purchasing decisions, particularly in the welding industry where equipment reliability is paramount for both hobbyists and professionals alike.

In addition to the robust warranty, Weldpro takes customer support seriously. They offer multiple channels for assistance, ensuring that users have access to help when they need it most. Customers can reach out to the support team via a dedicated phone number or email, making it easy to get answers to questions regarding the product, troubleshooting, or warranty claims. Furthermore, Weldpro maintains an informative website, which houses user manuals, FAQs, and additional resources designed to assist customers in maximizing the use of their TIG welder. This proactive approach to customer support reinforces Weldpro’s reputation as a reliable brand in the welding machine market.

Conclusion: Is the Weldpro TIG ACDC 200GD welder Right for You?

In evaluating the suitability of the Weldpro 200A AC/DC Aluminum TIG Welder for your welding projects, several key features and benefits are noteworthy. This versatile welder offers both AC and DC capabilities, making it an ideal choice for various applications, including aluminum, stainless steel, and mild steel welding. The inclusion of the Pulse CK 17 Worldwide Superflex TIG Torch enhances precision, allowing for refined control over the welding process, which is particularly beneficial for intricate jobs.

Prospective buyers should consider their experience level when deciding if the weldpro mig welder meets their needs. For beginners, the user-friendly design and adjustable settings can facilitate the learning process, while experienced welders will appreciate the advanced features that allow for more complex welding tasks. Additionally, the welder’s portability makes it a practical option for both shop and field work, ensuring flexibility for varied welding projects.

Budget is another critical factor to consider. The weldpro tig 200 ac/dc is competitively priced for its class, providing exceptional value without compromising quality. This makes it an attractive option for both hobbyists and professionals seeking reliable equipment without breaking the bank. Furthermore, the availability of spare parts and accessories can help ensure that your investment continues to perform optimally over time.

Specific applications also influence whether the weldpro mig welder aligns with your welding requirements. For those focused on automotive, fabrication, or artistic welding projects, its features cater well to deliver excellent results. Overall, the Weldpro 200A AC/DC Aluminum TIG Welder stands out for its combination of versatility, ease of use, and affordability, making it a strong contender for anyone in the market for a reliable TIG welding solution. Ultimately, this model can serve a diverse range of users, provided that its features align with their welding objectives.